The science behind tablet compression that every formulator must know

In tablet manufacturing set up, compression is the most challenging step. How well a powder blend is compressed affects directly the tablet hardness (and friability), which in turn is related to dosage form integrity and bioavailability. Although a tablet press plays a crucial role in tablet compression, equally important is the preparation of powder blend to make it ready for compression. Understanding the physics and theory behind the compression process can help in managing these operations carefully. For high-dose, poorly compressible drugs, study of compression assumes paramount importance, especially when there is a non-linear relationship between compression force and tablet tensile strength. In addition to this, thorough understanding of compression also helps in resolving many tableting-related problems which most of the time are associated with different compression-related variables.

Before we dive deep into the physics of compaction, let us first understand tableting terminology. Often, these terms are used interchangeably and therefore, are interpreted incorrectly. Hence, it is important to first understand the correct meaning of these terms.

Having understood these terms correctly, let us now find out what actually happens when a tablet undergoes compaction.

Compaction

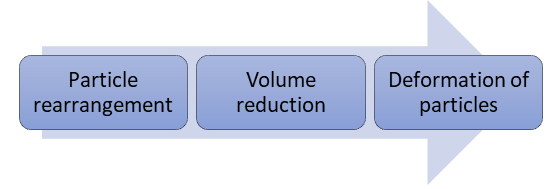

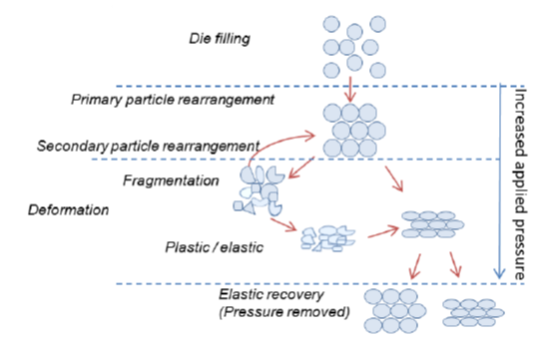

During compaction, powder particles are closely packed because of particle rearrangement, which leads to initial volume reduction. The particle rearrangement becomes difficult with increasing compaction force and causes particle deformation, and fragmentation. Bonds are established between the particles as they move into closer proximity to each other during the volume reduction process. These particle-particle interactions increase the mechanical strength of the powder bed and help in sustaining the rising compression forces leading to consolidation.

Though the compaction process mainly includes particle rearrangement, it is further followed by particle deformation under pressure. Smaller particles formed as a result of fracture of larger particles may undergo further rearrangement.

· Particle Rearrangement

During particle rearrangement, initially the particles are rearranged under low compaction pressure to form a closely packed structure. The smaller particles fill the voids between the larger ones to give a closer packing arrangement. As the compression force increases, the energy is evolved in the form of heat, because of interparticulate friction. Increase in the particle surface area further increases the possibility of forming interparticulate bonds. Particle rearrangement ceases after certain point of increasing compression force. Now the volume reduction is governed by plastic and elastic deformation and/or fragmentation of the particles.

Several powder characteristics such as particle size, particle size distribution, density, surface properties, and interparticulate voids affect the possible inter- or intraparticulate bonds among the particles. Process variables such as moisture content, flow rate, particle diameter, and die-cavity diameter also impact the particle-particle interactions.

· Volume reduction

The extent of volume reduction of powder bed depends on the mechanical properties of the powder and the type of volume reduction mechanisms involved. Particle size and speed of compression will in turn influence the mechanical properties of the material.

- Brittle materials generally undergo extensive fragmentation which result in tablets of relatively high porosity because of the large number of bonding points that are created, which prevent further volume reduction.

- A ductile material tends to form tablets of low porosity because the high degree of plastic deformation enables the particles to move very close to each other.

- Different crystal habits such as spherical, cubical, and acicular, have different tendencies to pack in a close structure.

· Deformation of Particles

When the compression force is applied to the powder bed, it causes development of stress and local deformation of the particles. Particle deformation occurs in many ways:

- Elastic deformation – Elastic substances exhibit reversible process, i.e., particles when deformed resume their original shape instantaneously.

- Plastic deformation – Plastic substances exhibit irreversible process, i.e., deformation of particles results in a permanent change of the particles shape.

- Viscoelastic deformation – A viscoelastic material will return to its original shape after any deforming force has been removed. However, it will take time to do so.

- Brittle fracture – Brittle particles generally increase more contact points for bonding because of the fragmentation of the original particles into smaller units.

The type of deformation depends on the physical properties of the material as well as on the rate and magnitude of the applied force and the duration of locally induced stress.

· Time Dependence of Compaction Process

The rate at which the force is applied to the powder bed is another important factor for successful compression. A plastically deforming solid, when loaded or unloaded too rapidly, may exhibit brittle fracture because plastic deformation is time dependent. In such case, increasing the machine speed may cause structural failure of tableting. On the other hand, increasing the dwell time (speed of compaction) under the compression load will resume the plastic deformation, leading to more integration. Dwell time also affects the compactibility of the powder as well as lamination, capping, and picking of tablets. Application of compression force for a longer period of time (extended dwell time) results in viscoelastic behavior during compression of tablets at normal production speed as well as at slower speeds.

Compression Cycle

Understanding the different stages of compression cycle helps to understand the mechanism by which powder materials are compressed. It also gives insight about the various formulation and compression variables which affect the finished tablet.

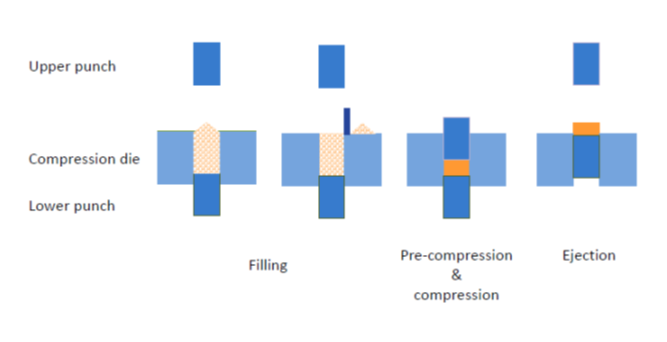

Compression cycle is divided into following 4 phases:

- Precompression

- Main compression

- Decompression

- Ejection

· Precompression

As the name suggests, precompression is the stage where small force is applied to the powder bed in order to form partial compacts before undergoing the main compression. To achieve this, the precompression roller is usually kept smaller than the main compression roller. However, the size of the precompression roller and the magnitude of the precompression force can change depending upon the type of the material being compressed. For example, powders which are prone to brittle fracture, higher precompression force than main compression leads to higher tablet hardness. However, powders with elastic property require gradual application of force to reduce elastic recovery and allow stress relaxation. An optimal tablet formation is achieved with similar sizes of main and precompression rollers with similar forces.

· Main compression

During main compression interparticulate bonds are formed as a result of particle rearrangement followed by particle fragmentation and/or deformation. For powders with viscoelastic properties, compression conditions need special attention as these affect the compression behavior of the material and subsequent tableting process.

· Decompression

After compression the tablet undergoes elastic recovery which gives rise to different types of stresses. If these stresses are not sustained by the tablet, it can lead to structure failures. For example, tablet capping or lamination occurs when the tablets show high rate and degree of elastic recovery. Fracturing of surfaces occur when the tablet undergoes brittle fracture during decompression. Plastic deformation is another way to relieve stress and is time dependent. The rate of decompression also affects the tablet structure failure. Therefore, the use of a plastically deforming agent such as PVP, MCC is recommended.

· Ejection

Ejection is the last stage of compression cycle which involves breaking of the adhesions between die wall and compact surface. When the tablet is ejected from the die wall, it causes friction due to shear between the tablet and the die wall further resulting in heat generation. Absorption of this heat further leads to bond formation. Lubrication generally reduces ejection forces thereby reducing the possibility of capping or laminating. Powders of smaller particle size require higher ejection forces to remove the tablets.

Overall understanding the theoretical aspects of compression helps in selecting the optimal compression conditions for a given tablet product and at the same time can avoid the potential tableting problems thus saving significant time and resources.

ACG is the only supplier in the world offering integrated manufacturing solutions to the global pharmaceutical industry. We manufacture world-class tablet compression machines and advanced tablet coating systems that meet the diverse needs of the customers, right from R&D to manufacturing scale. Our Protab 700 is a new benchmark in high-speed tableting which simplifies all aspects of the tableting process for paramount efficiency. For further details please contact us at: sales.pam@acg-world.com

References

-

Patel S, Kaushal AM, Bansal AK. Compression Physics in the Formulation Development of Tablets. Critical ReviewsTM in Therapeutic Drug Carrier Systems, 2006; 23(1):1–65

-

Mohan S. Compression Physics of Pharmaceutical Powders: A Review. Int J of Pharm Sci and Research. Published on June 01, 2012. Available from: http://ijpsr.com/bft-article/compression-physics-of-pharmaceutical-powders-a-review/?view=fulltext