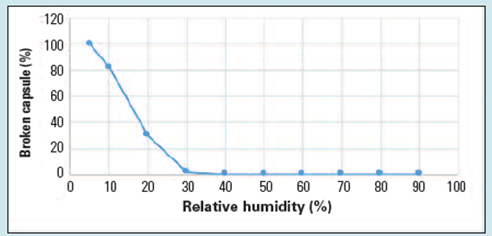

Gelatin capsules constitute a major share of the capsule market today. The prediction that the global market of capsules is expected to grow from $1.5 billion in 2016 to $2.21 billion in 2021 shows that gelatin capsules are still performing well, irrespective of the other capsule options available in the market.i The long-term usage and safety record of gelatin capsules indicate that they are a reliable dosage form. Although gelatin capsules have many desirable properties for a dosage form, certain other properties of gelatin must be considered more closely during product development. One such property is the potential of gelatin capsules to lose moisture and become brittle when they are stored at low relative humidity (RH), contain hygroscopic formulations, or are exposed to desiccants. Gelatin capsules usually tend to become brittle at an RH below 40% (Figure 1).

Figure 1: Percentage of capsules broken vs. relative humidity

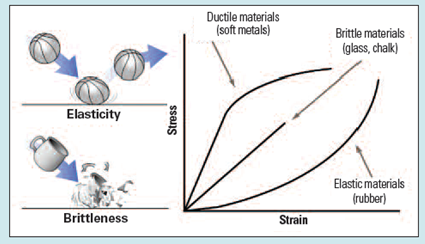

Before we move on to consider the different approaches that can be adopted to reduce the brittleness of gelatin capsules, the property of brittleness should first be understood. A material is said to be brittle when it breaks without undergoing permanent distortion. This property is exactly opposite to elasticity, which is defined as a material’s ability to be stretched or deformed and then be able to return to its original size. Elasticity is observed when a material (a polymer, in the case of gelatin capsules) is subjected to force; this energy is accommodated through various processes, such as deformation, molecular movements (vibration, rotation, and small translations), and heat. However, such modes of movement are not observed in brittle materials. Instead, the force applied is confined within a small localized area, causing the direct rupture of bonds (Figure 2).

Hard gelatin films often require plasticizers during preparation to reduce the stiffness of the gelatin. Along with the polymer, plasticizers reduce the cohesive intermolecular forces and impart a degree of flexibility. Water (13–16% w/w)ii is the most commonly used plasticizer in hard gelatin capsules. Consequently, at low RH, the capsules lose moisture and become brittle.

Figure 2: Brittleness vs. elasticity iii, iv, v

The brittleness of capsules has a significant negative impact on the stability of the filled material and on the aesthetics visual appeal of the products; therefore, it should be closely monitored. In the forthcoming blog posts, we will talk about the other factors that contribute to the brittleness of gelatin capsules. An in-depth knowledge of these factors will help pharma manufacturers devise different strategies to prevent it.