Pigments are used heavily during capsule manufacture. Colored capsules assist in the identification of dosage forms for patients. A uniquely colored capsule provides a strong anti-counterfeiting measure for a drug. In addition, from a branding perspective, color creates an excellent brand differentiation opportunity for drug manufacturers.

To manufacture colored capsules, pigments are usually preferred to water-soluble dyes. Pigments are water-insoluble colorants that selectively absorb a particular wavelength of light and reflect others. This difference in the proportion of wavelength is perceived as color. By dispersing the light, pigments produce opacity and create a barrier to protect gelatin against harmful radiation. The most common pigment used in capsules is titanium dioxide. It has a refractive index (RI) of 2.27–2.71, which is markedly different from that of gelatin (RI = 1.24). This difference in RI helps to create a high barrier to radiation, protecting the gelatin as light passes from gelatin (low RI) to titanium dioxide (high RI).

From the perspective of capsule brittleness, pigments play an important role in mechanical properties; as the proportion of pigments is increased, brittleness is also increased. Hence, the pigment content is a critical part of capsule design. An insufficient amount of pigment may fail to protect the gelatin from UV radiation, whereas an excessive amount may result in brittle capsules.

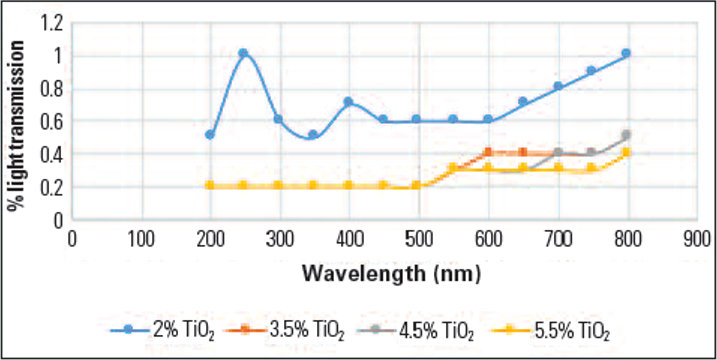

The following figure shows the impact of the quantity of titanium dioxide on the UV/VIS spectrum of gelatin capsules.

Figure: UV/VIS spectra of gelatin capsules containing different TiO2 concentrations[i]

Titanium dioxide at a concentration of approximately 3% shows very low light transmission. Increasing the pigment concentration further does not result in increased drug protection but increases the brittleness of the gelatin capsules. Hence, it is advisable to not use a high amount of titanium dioxide to color gelatin capsules.

Capsule manufacturers must closely consider the preparation conditions of the capsule shells, including the temperature and relative humidity of the capsule preparation area; we have already learned that gelatin shows many characteristics typical of a synthetic polymer. Therefore, its mechanical properties are strongly influenced by the molecular weight and molecular weight distribution, similar to any other polymer. Accordingly, manufacturers must select an optimum molecular weight that will provide sufficient mechanical properties and also be easy to process.

Gelatin, when subjected to excessive heat for a prolonged period, can cause polymer chain fragmentation, which, in turn, reduces the molecular weight. This can lead to brittle capsules with a markedly lower capsule performance. Therefore, during manufacturing, when gelatin is required to be heated, it is recommended to keep the heating period as short as possible. Usually, gelatin is dissolved at 70°C to 80°C in demineralized water, in jacketed stainless steel tanks, which takes approximately 1 hour.

In the next blog we will see how quality control tests can help to avoid the brittleness in gelatin capsules.